Superconductivity

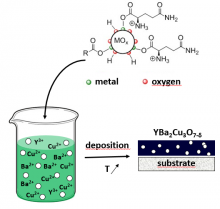

Superconductors are promising for various applications, ranging from magnets to generators and transformers. However, the performance of these materials decreases dramatically in high magnetic fields. Magnetic flux quanta, i.e. vortices, appear in a superconducting film upon applying a magnetic field. These vortices move throughout the superconductor under the influence of a Lorentz force, causing thermal dissipation and a reduction in JC. Vortices can be immobilized, or pinned, by the introduction of non-superconducting defects of the size of their core, i.e. a few nm. These so called artificial pinning centers (APCs) should effectively decrease the magnetic field dependence of JC. The production of such a superconducting coating comprises a number of steps which we focus on in our research group:

(1) Synthesis of metal oxide nanocrystals, using either classical hot-injection surfactant-assisted synthesis or microwave-assisted surfactant-free solvothermal synthesis. Both methods are investigated intensively and reaction mechanisms are studied with care. The synthesis of crystalline (binary) metal oxide nanoparticles is envisaged. The resulting nanocrystals are analyzed via XRD, DLS and TEM analysis.

(2) Stabilization of the nanocrystals in the YBCO precursor: After synthesis, the NCs are often capped with fatty acids to prevent agglomeration and ensure colloidal stability in apolar solvents. Yet, YBCO precursors are methanol based, and therefore, the original ligand (fatty acid) is exchanged for polar ligands (e.g., amino acid). To understand the NCs surface chemistry our main tool is 1H solution NMR spectroscopy (in collaboration with Prof. J. Martins).

(3) Deposition and thermal treatment of the precursor is the last step in the coating process. The YBCO precursor solution, containing the stabilized nanocrystals, is deposited on a substrate via ink-jet printing. Droplet formation, flight, impact and wetting are of great importance when using ink-jet printing. Therefore, the monitoring and analysis of this behavior is essential. For this, a strobe controlled illumination system was custom build in-house and allows monitoring of droplet formation and travelling, which gives essential understandings for tuning ink composition and jetting parameters. Because patterning of the superconducting film can reduce the losses when working in alternating current or magnetic field applications, direct patterning of YBCO on the substrates is also investigated. Subsequently, the coatings and patterns are thermally treated to obtain the desired YBCO coating. This heat treatment requires optimization regarding temperature profiles and reaction atmosphere. The results can be analyzed through structural (e.g., FIB-SEM, TEM, XRD) and magnetic analysis (e.g., SQUID and transport measurements). After thermal processing, patterns 40 to 220 µm wide and 100 to 500 nm thick were obtained using printheads with orifice diameters ranging from 9 to 60 µm. By tuning the drying step and by performing multiple depositions, sharp edged patterns with almost no coffee ring effect were obtained on the used substrates.

#Superconductivity #Superconductors #ZeroResistance #QuantumPhysics #Cryogenics #MagneticField #HighTemperatureSuperconductors #CooperPairs #MeissnerEffect #SuperconductingMaterials #SuperconductingTechnology #SuperconductingApplications #SuperconductingPowerTransmission #QuantumMechanics #EnergyEfficiency

Twitter:https://twitter.com/magnolia2523

Pinterest:https://in.pinterest.com/condensc/

Comments

Post a Comment